Společnost Yaskawa nabízí portfolio produktů, díky kterým je předním výrobcem v oblasti měničů střídavého proudu, servopohonů, řídicí technologie a robotiky.

Abrazivní Tryskání

Robotická úprava povrchu pomocí abrazivního tryskání, pískování, tryskání suchým ledem, tryskání Co2

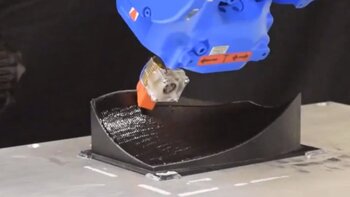

číst víceAditivní výroba

3D tisk a rychlá výroba prototypů, aditivní výroba pomocí elektronického oblouku (WAAM), laserové oplášťování, dekorace pomocí robotů Motoman

číst víceBodové a válcové svařování

Resistance Welding, Spot Welding, Roll Seam Welding, Stud/Nut Welding

číst víceBroušení | Leštění

Robotic Surface Finishing, Grinding, Sanding, Polishing, Brushing of Workpiece Surfaces

číst víceDávkování | Těsnění

Robotic Dosing Applications of adhesive material, Sealing, Dosing, Dispensing, Glueing and Cladding

číst víceKompletace | Balení

Picking, packing, picking and boxing, packaging in packaging applications with Motoman robots

číst víceKontrola kvality

Robotic quality inspection and control, handling inspection devices (metrology, scanners)

číst víceLaserové svařování

Laser Welding, Remote Laser Welding, Laser Soldering / Brazing with Motoman Robots

číst víceMechanické spojování

Mechanical Fastening and Joining Technologies, Clinching, Screwdriving, Riveting, Part Feeding, Blind Riveting, Press Fitting with Motoman Robots

číst víceMobilní roboti

AMR (Autonomous Mobile Robots), AGV (Autonomous Guided Vehicles), FTS (Flexible Transport Systems) with Motoman Robots

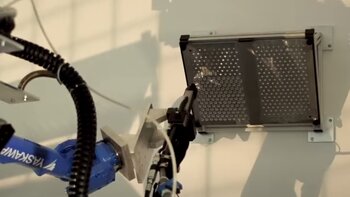

číst víceObsluha strojů

Loading and unloading machines and CNC machine tools, injection moulding machines and forging presses with Motoman Robots

číst víceOdstraňování materiálů

Material Removal, Machining, Milling, Drilling/Boring, Reaming, Finishing, Polishing, Grinding, Deburring, and more with Motoman Robots

číst víceOšetřování lisu

Press Tending, Press-to-Press Automation, Loading and unloading presses with Motoman Robots

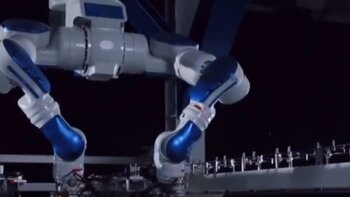

číst vícePaletizace

Palletizing and Depalletizing, Random Palletizing with Motoman Robots and Collaborative Robots

číst vícePick & Place

Pick and Place, High Speed Picking, Bin Picking, Vision- and AI-based order picking, part feeding with Motoman Robots.

číst vícePumps & Compressors

Compressed air and vacuum play an important role in many industrial processes. Whether for driving pneumatic tools or for surface coating. Speedcontrolled systems combine top performance with maximum energy efficiency.

číst víceŘezání | Střihání

Robotic cutting of material, with mechanical tools, sawing, ultrasonic cutting and trimming, waterjet cutting, plasma cutting, laser cutting

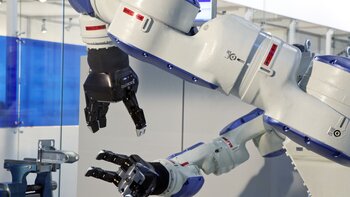

číst víceRobotická inspirace...

Fascinating and Innovative Application Solutions with Motoman Robots

číst víceŠtítkování | Značení

Labelling, CMT-Marking, Laser Marking, Engraving and Printing with Motoman Robots

číst více